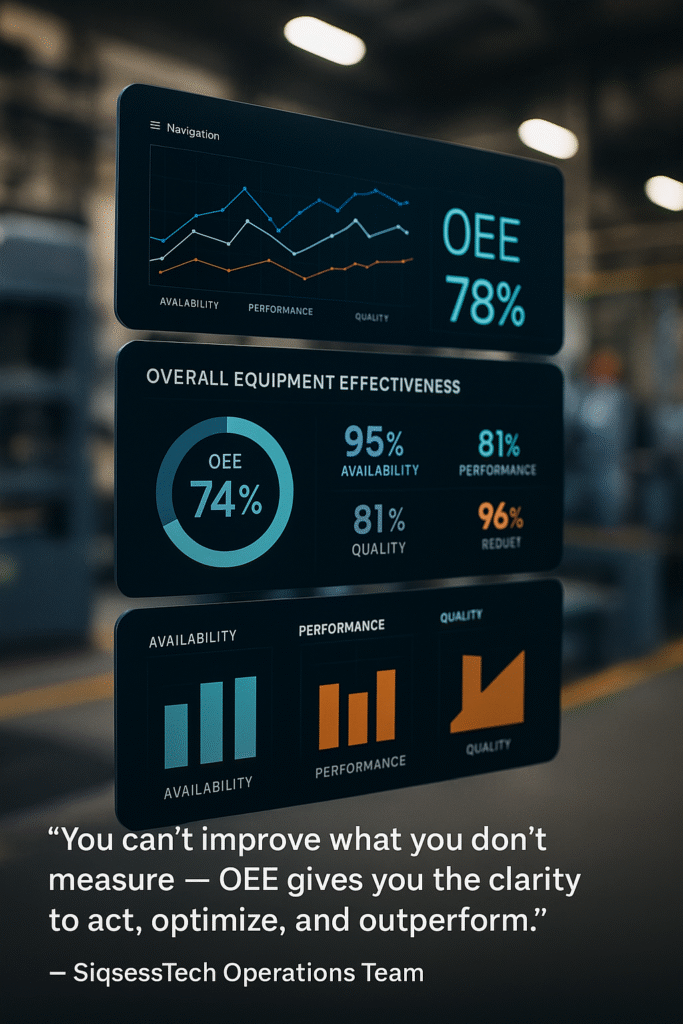

POptimize Production with Real-Time OEE Insights

In a world of high-speed manufacturing, every second matters. Overall Equipment Effectiveness (OEE) is the gold standard metric to evaluate how effectively your equipment is running. With IoT-powered analytics, manufacturers can now measure and act on real-time performance data like never before.

OEE tracks three key factors:

- Availability – Reduce unplanned downtime and streamline maintenance.

- Performance – Monitor production speed versus ideal cycle times.

- Quality – Detect defects instantly to minimize waste.

By integrating IoT sensors and dashboards, businesses gain instant visibility into operational bottlenecks, enabling proactive decisions that enhance productivity, reduce costs, and drive ROI.

Achieve More with Less Downtime.

From the plant floor to the cloud, OEE with IoT empowers your teams to shift from reactive to predictive, unlocking the full potential of your assets.

Modern manufacturing demands more than routine monitoring — it requires actionable insights. With real-time OEE dashboards powered by IoT, manufacturers can detect inefficiencies at the source, minimize downtime, and maximize throughput. The difference between good and great operations lies in data clarity and speed of response.

“You can’t improve what you don’t measure — OEE gives you the clarity to act, optimize, and outperform.”

— SiqsessTech Operations Team

Maximize Efficiency with Real-Time Performance Tracking

Unlock the full potential of your operations by leveraging data-driven insights into equipment performance, availability, and quality. Our OEE solutions provide a comprehensive view of production effectiveness, helping identify bottlenecks, reduce downtime, and drive continuous improvement across your facility.

Maximize Uptime. Minimize Waste. Optimize Production.

Through real-time monitoring and intelligent analytics, our OEE tools empower your teams to make informed decisions faster. Track performance trends, uncover root causes of inefficiencies, and implement targeted actions that elevate productivity—day in and day out.